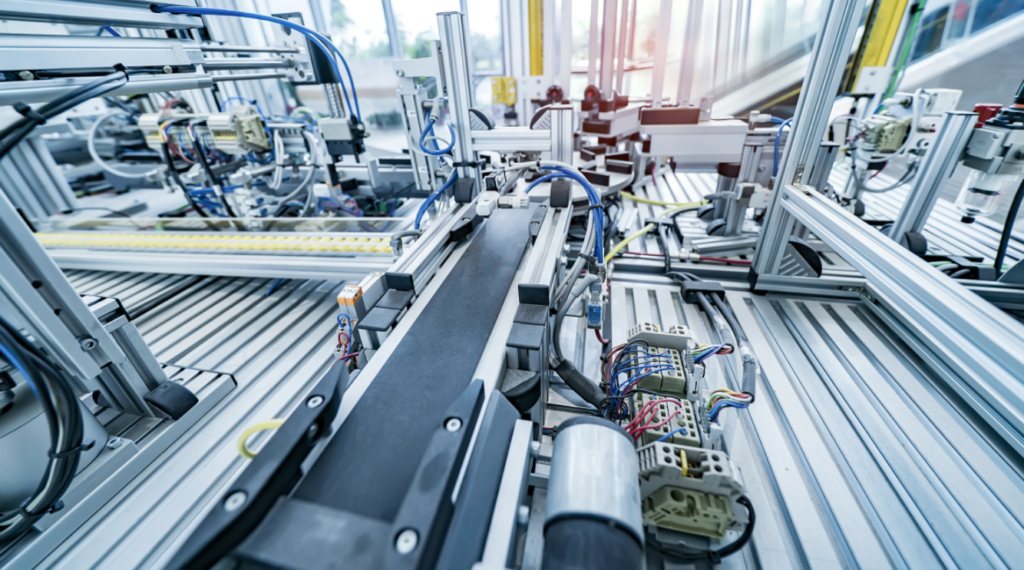

Sensor cable is the connection line used on various sensors, which is an important part of the sensor. It is mainly used to connect sensors and detection equipment to detect heat, light, sound, motion, gas, liquid or other physical characteristics, and convert these information into signals and send them back to the monitoring equipment for processing and analysis, and finally obtain the relevant information of the target object.

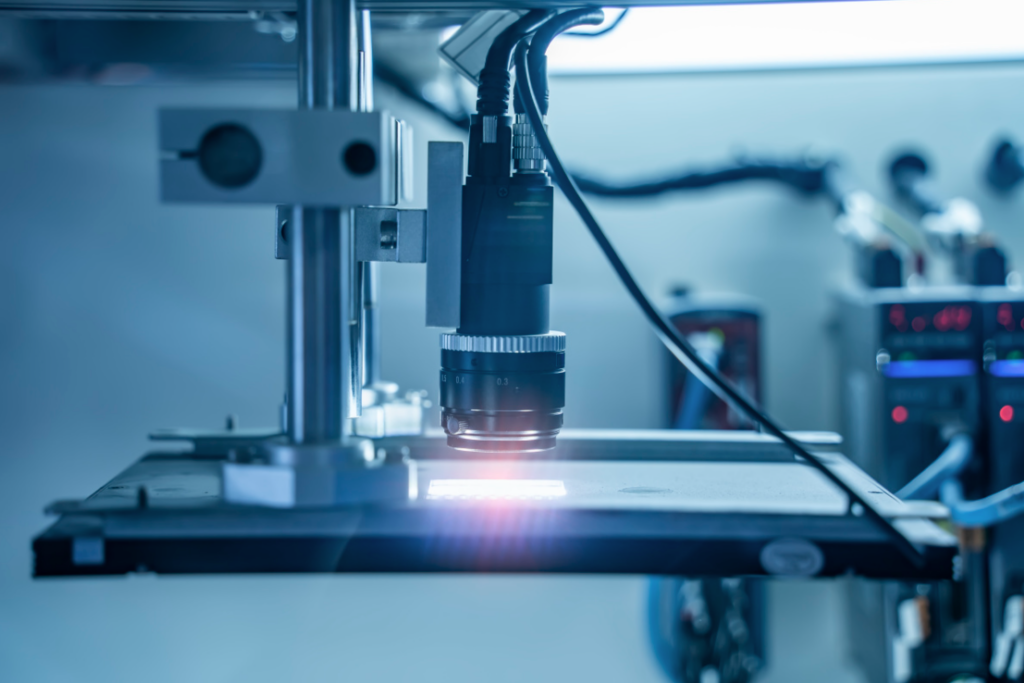

There are many types of sensors, including temperature sensors, infrared (IR) sensors, fluid/flow control sensors, ultrasonic sensors, piezoelectric accelerometers, pressure sensors, moisture/humidity sensors, photoelectric sensors, proximity sensors, vibration and touch sensors, and more.

As smart products and devices multiply, so does the need for cables to connect multiple types of sensors. The quality and performance of the cable itself is the key factor to ensure the accuracy, reliability and stability of the transmitted signal.

Sensor cable as a high-precision, high-reliability cable, compared with other ordinary control cables, the main advantage is strong signal transmission performance, anti-attenuation, so in the selection should pay attention to the following points:

Conductor:

Sensor cable for signal transmission requirements are relatively high, the use of special ultrafine silver-plated copper or tin-plated copper conductor, low attenuation, excellent transmission performance, good softness.

Shield:

Tin-plated copper or silver-plated copper braid shielding can effectively block electromagnetic interference, effectively prevent the impact of external electrostatic interference, electromagnetic interference and high-frequency interference on the transmission signal, and improve the quality of transmitted data.

The irradiated cross-linked polyene material has good electrical properties and heat resistance, and is used as the insulation layer and sheath of sensor cables, so that the cables can provide safe and reliable signal transmission in high temperature and high voltage working environment.

Insulation and sheath:

The irradiated cross-linked polyene material has good electrical properties and heat resistance, and is used as the insulation layer and sheath of sensor cables, so that the cables can provide safe and reliable signal transmission in high temperature and high voltage working environment.

These high standards of materials make the sensor cable have many excellent properties:

High wear resistance:

Sensor cables have high wear resistance and can withstand repeated bending operations.

High anti-interference:

Sensor cables need to have high anti-interference, can effectively resist external electromagnetic signals, radio frequency interference and other interference factors, to ensure the accuracy and stability of signal transmission.

High temperature tolerance:

Since the sensor installation and detection site usually has a high or low temperature environment, the sensor cable needs to have a high/low temperature tolerance to ensure normal operation in high/low temperature environments.

In general, sensor cable is a kind of ultra-fine, high-performance cable products, widely used in industrial, transportation, automotive and medical fields.

Tecsteck cable focuses on the development and production of sensor cables. The sensor cables produced are: temperature sensor cable, speed sensor cable (photoelectric speed sensor, Hall speed sensor), composite sensor cable, acceleration, wind speed sensor cable, etc.

It has good oil resistance, wear resistance, acid and alkali resistance, corrosion resistance, waterproof and shielding properties, strong tensile strength, excellent pressure resistance and high reliability.

Tecsteck cable market share in the sensor cable segment is more than 95%, and we hope that industry practitioners can choose reliable sensor cables to ensure the performance of sensors.