The term cable wire harness is commonplace in the world of electronics and electrical systems, but it has a significant impact on a wide range of industries. From automotive manufacturing to aerospace engineering, household appliances to telecommunications, cable wire harnesses ensure complex systems operate effectively and efficiently. As specialist cable wire harness manufacturers, we aim to shed light on what a cable wire harness is, delve into its main uses, and highlight its importance in various sectors.

What is a cable wire harness?

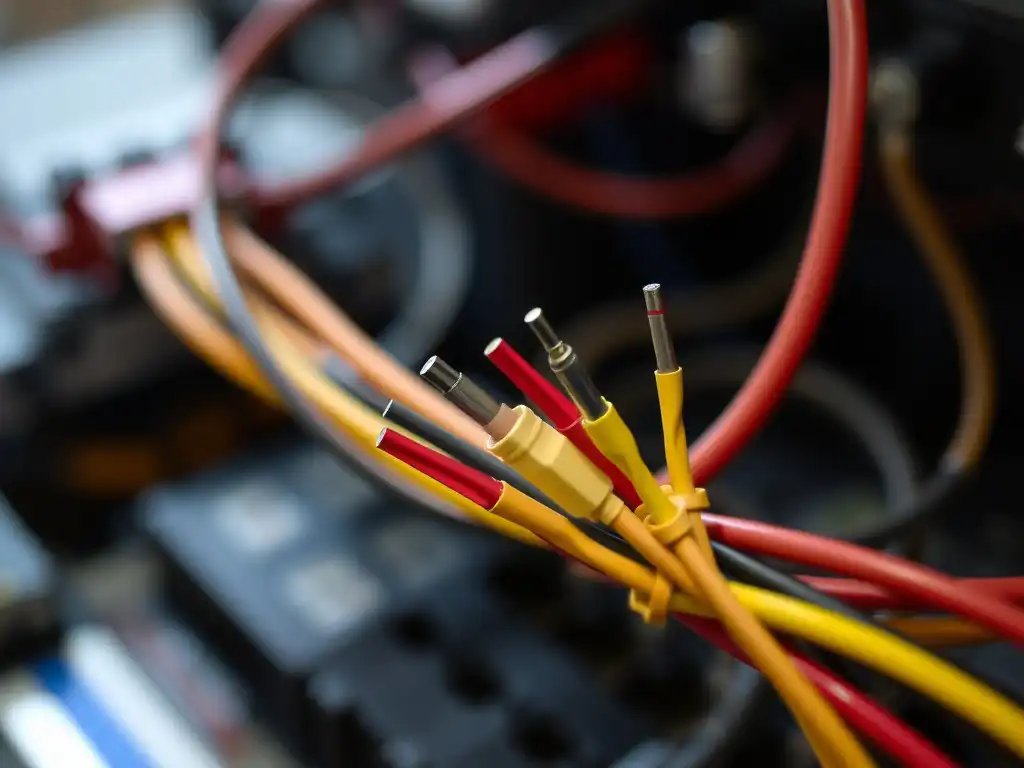

A cable wire harness, also known as a wiring harness, wire assembly, or cable assembly, is an organized group of wires, cables, and connectors that transmit power and signals within a device or system. The main components include

- Wireless cables are the core components that carry current or data signals.

2. connectors: these endpoints ensure a secure and stable connection between the various parts of the system.

3. terminals: these are the metal ends of the wires that facilitate connection to the connectors.

4. insulating materials: these materials protect the wires from environmental factors and prevent short-circuiting.

5. protective covers, tapes, and ties: these parts organize and secure the wires to reduce abrasion.

Professional engineering and precise assembly are essential to developing efficient cable wire harnesses. This is where our expertise as a specialized manufacturer comes into play, ensuring that each harness meets stringent quality standards and specific customer requirements.

Uses of cable wire harnesses:

The uses of cable wire harnesses are manifold, covering efficiency, safety, and organization within electrical systems. Here are some essential functions

- Simplified manufacturing:

Cable wire harnesses greatly simplify the manufacturing process. By pre-assembling wires and connectors into a single unit, they reduce the complexity and time required for installation. This simplification is especially beneficial in the automotive and aerospace industries, which require many electrical connections.

2. Improved safety:

One of the critical purposes of cable wire harnesses is to improve safety. An organized wire assembly reduces the risk of electrical short circuits and minimizes the possibility of loose or exposed wires, thus avoiding electrical fires or malfunctions. In addition, using durable insulation and protective sheathing means that cables can better withstand environmental hazards such as moisture, heat, or vibration.

3. Enhanced performance and reliability:

By ensuring that all connections are safe and secure, cable wire harnesses help improve the reliable performance of electronic systems. Carefully crafted harnesses enhance signal quality and reduce electrical noise, ensuring uninterrupted data and power transmission. This reliability is critical in high-risk environments such as military applications or medical equipment.

4. Economic efficiency:

Cable wire harnesses increase economic efficiency by reducing labor and material waste costs. A streamlined manufacturing process means less time spent assembling individual components, and an organized design minimizes errors and rework. In addition, standardized harnesses simplify maintenance and troubleshooting, potentially reducing costly downtime.

Cable wire harness Applications:

Cable wire harnesses can be used in a multitude of industries, each requiring customized designs to meet specific requirements:

- automotive industry:

In vehicles, cable wire harnesses connect various electrical and electronic components, such as the engine, dashboard controls, lights, and infotainment systems. These harnesses must be ruggedized to withstand the harsh conditions inside the vehicle, including extreme temperatures and vibrations.

2. Aerospace industry:

In the aerospace industry, reliability and precision cannot be compromised. Cable wire harnesses in this sector are designed to handle high altitudes, strong vibrations, and extreme temperatures. They ensure seamless communication and power distribution within airplanes, satellites, and space exploration vehicles.

3. Medical equipment:

Medical equipment demands impeccable performance and reliability. Cable wire harnesses in medical equipment help transmit power and data to diagnostic equipment, imaging systems, and patient monitoring tools, playing a direct role in patient care and safety.

4. Industrial Machinery:

In manufacturing and industrial environments, cable wire harnesses organize the wiring of machinery and robotic systems. This organization contributes to efficient operation, easy maintenance, and quick repairs.

5. consumer electronics:

From home appliances to personal electronics, cable wire harnesses ensure the smooth functioning of consumer electronics. These harnesses contribute to modern gadgets’ compact and efficient design and enhance the user experience.

As a specialized cable wire harness manufacturer, we understand these components’ critical role in different industries. A well-designed cable wire harness is more than just a bundle of wires; it is the backbone of electrical and electronic systems, ensuring efficiency, safety, performance, and reliability. By providing high-quality, customized solutions, we enable our customers to create cutting-edge, reliable products that drive progress and innovation.