Automotive wiring harnesses play a vital role in the electrical systems of modern transportation. They connect the various electronic components of the vehicle to transmit power and signals. As a professional automotive wiring harness manufacturer, we understand the importance of using quality and suitable materials for the harness’s performance. Below, we will detail some materials commonly used to manufacture automotive wiring harnesses.

1. Copper

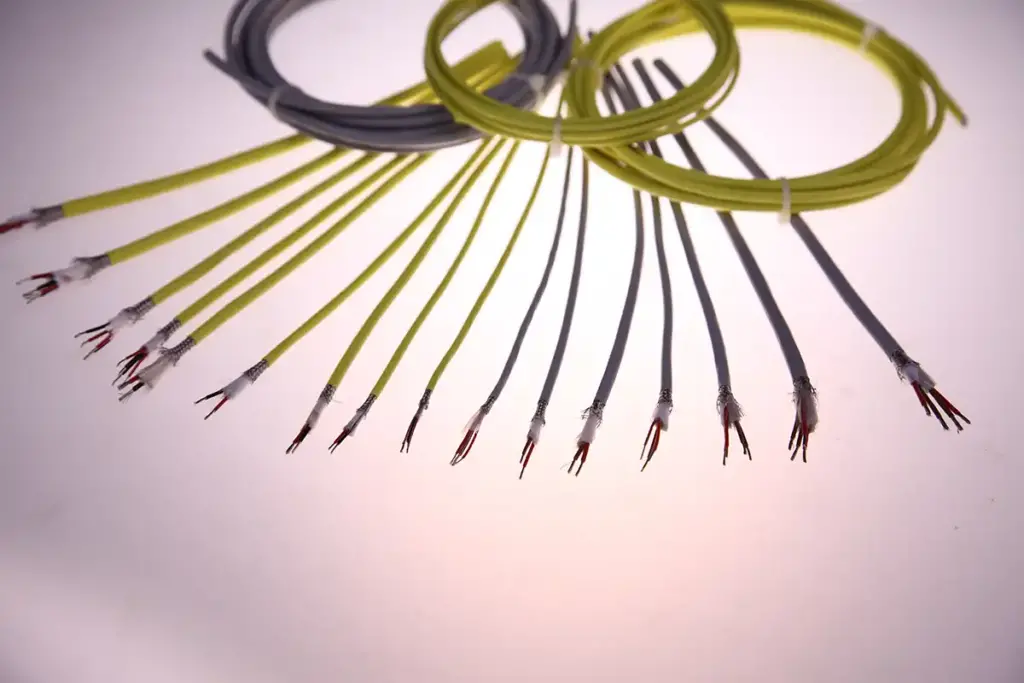

Copper is the primary material used as a conductor in automotive wiring harnesses. Due to its excellent electrical conductivity and mechanical strength, copper is preferred for wiring harnesses. Copper’s high conductivity ensures efficient current transfer, while its flexibility and malleability make it easy to process and install. In addition, copper is highly resistant to oxidation, which is critical in automotive environments where prolonged periods of use are standard.

2. Aluminum

With the rise of energy efficiency and environmental protection, aluminum is gradually replacing copper as a conductor material in some cases. Aluminum is lighter than copper, which reduces the vehicle’s weight and improves fuel efficiency. Although aluminum is not as electrically conductive as copper, a similar effect can be achieved by increasing the cross-sectional area of the conductor. However, aluminum connections require special terminals and processes to avoid corrosion and poor contact.

3. Insulation Materials

Insulation materials play a crucial role in protecting wires and ensuring the safety of circuits. There are several common insulating materials:

a.Polyvinyl Chloride(PVC)

PVC is a popular insulating material because of its low cost and sound insulating properties. It is also heat—and chemical-resistant and can be quickly processed into various shapes and thicknesses. However, PVC’s performance deteriorates in extreme temperatures, so it is mainly used in non-extreme applications.

b.Cross-linked Polyethylene(XLPE)

XLPE has better resistance to high temperatures and aging than PVC. Therefore, XLPE wire harnesses are more reliable and durable in high-temperature environments. It also has higher mechanical strength and is suitable for heavy-duty wire systems.

c.Polyimide(PI)

Polyimide has excellent high-temperature resistance and mechanical strength and is commonly used in the wire harness’s high-temperature and high-stress environment. This high-performance material is often found in aerospace and motorsports applications requiring extreme reliability.

4. Sheathing Materials

The sheathing is required to protect the wire harness from the external environment. Sheathing materials need good mechanical protection properties and water, dust, and corrosion resistance.

a.Polyurethane(PU)

Polyurethane has excellent abrasion resistance and low-temperature flexibility, making it ideal for outdoor and high-intensity work environments. It also has superior UV and oil resistance.

b.Thermoplastic Elastomer(TPE)

TPE combines rubber’s flexibility with plastic’s processability, and its excellent elasticity and durability make it an ideal choice for sheath materials. In addition, TPE can provide better waterproofing and dust proofing.

5. Connectors and Terminals

Connectors and terminals for wire harnesses are usually made of brass or tinned copper. Brass has good corrosion resistance, while tinned copper improves oxidation resistance and provides better electrical contact during connection. Different splice and connector designs meet the needs of various complex circuits and environments.

The materials used in automotive wiring harnesses directly impact their performance and reliability. Materials such as copper, aluminum, PVC, XLPE, PU, and brass each have their strengths, and choosing according to different application scenarios and needs is the key to harnessing design and manufacturing. As a professional manufacturer of automotive wiring harnesses, we will continue to improve the technology and material application capabilities to provide high-quality and highly reliable wiring harness products for the automotive industry.