Advantages of irradiated cross linked cable for rail transit vehicles

Advantages of irradiated cross-linked cable

- The teaching flow rate of the cable is greatly improved: the temperature resistance level of Fuzhao XLPE electric unit can be increased from 90°C to 150°C of ordinary XLPE cables, the short-term short-circuit temperature can be increased from 250°C to 350°C, and the flow rate of cables of the same specification can be increased by 15%~45%.

- It can realize the low-smoke, halogen-free, flame-retardant and other green and environmental protection functions of the cross-linked polyethylene field body. Irradiation cross-linked cables avoid undesirable phenomena such as the infiltration of a large amount of Mg(OH)2 and AL(OH)2 flame retardants into polyfield hydrocarbon materials in order to achieve low-smoke, halogen-free, and flame-retardant functions, resulting in pre-crosslinking in ordinary cross-linking processes and a large drop in insulation resistance due to moisture absorption of the insulating layer. Irradiation cross-linking is a high-tech industry that cross-links polyolefin materials at room temperature and in air, and is the best way to achieve low-smoke, halogen-free, and flame-retardant cross-linked polyethylene.

- Excellent aging performance: the aging temperature of the cable’s absolute image layer is increased from 135°C to 180°C for ordinary cross-linked cables, and the extended service life of the cable in the course of cyclic heating ensures that the cable can be used normally for 50 years.

- Stable product quality: The mechanical and physical properties of the polymer after cross-linking depend on the degree of cross-linking of the polymer molecule. The degree of cross-linking of the cross-linking process depends on the radiation dose of the electron beam. The radiation dose of the electron beam is directly set by the computer system, which avoids the randomness of the chemical reaction in the cross-linking process of ordinary cross-linked materials.

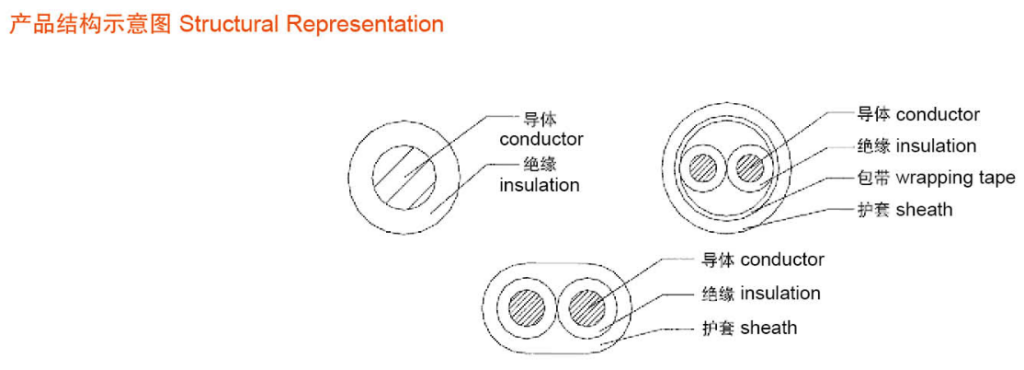

Data cable Network cable

Irradiation cross-linked polyolefin insulation cables for fixed laying

use

It is mainly suitable for flame-retardant or non-flame-retardant wires and cables with a rated voltage of 450/750V and below, used in fixed laying places, and with a long-term working temperature of 90°C, 105°C, 125°C or 150°C.

Technical Parameters

- The flame-retardant finished wire or cable has passed the bundled combustion test specified in GB/T18380.

- The fire-resistant finished wire or cable has passed the fire-resistant performance test specified in GB/T19216.

- The low-smoke halogen-free wire or cable has passed the smoke density test specified in GB/T17651, and its light transmittance should not be less than 60%.

- For low-smoke, halogen-free wires or cables, the pH value shall not be less than 4.3, and the conductivity shall not be greater than 10μS/mm through the determination of the halogen acid gas content specified in GB/T17650.

- The non-flame retardant PVC sheathed cable has passed the single vertical burning test in GB/T18380.

Features - Stable electrical and insulating properties;

- High temperature resistance grade, can be produced at 90°C, 105°C, 125°C or 150°C, with large carrying capacity and strong overload protection performance;

- It has the characteristics of halogen-free, low smoke, low toxicity and environmental protection;

- The density of cable combustion smoke is small;

- It has excellent flame retardant performance and can pass the single vertical burning test and bundle burning test.

50 Ω 75 Ω coaxial cable

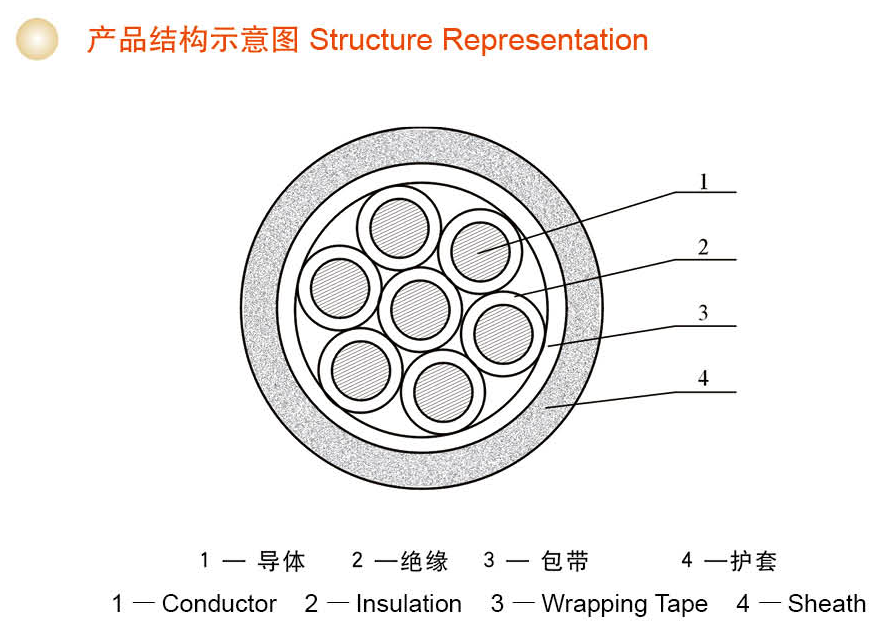

Irradiation cross-linked polyolefin insulation, halogen-free, low-smoke, flame-retardant cables for rail transit vehicles

Executive standard

This product implements GB/T12528 standard

use

This product is suitable for power distribution system, control system, electrical device of signal system for rail transit with AC rated voltage 3kV and below. It is especially suitable for use under the conditions of high working temperature, wear resistance, oil resistance and softness.

Features

- Rated voltage (AC) is divided into four grades: 500V, 750V, 1500V, 3000V.

- The long-term allowable maximum working temperature of the conductor of the cable is 100°C, 125°C, 150°C.

- Bending radius: the outer diameter of the cable is 20mm and below should not be less than 6D; the outer diameter of the cable is 20mm and above should not be less than 8D.

Main Specifications

- Conductor DC resistance complies with GB/T3956 regulations.

- The withstand voltage test of the finished cable complies with the provisions of GB/T12528.

- Halogen-free and low-smoke performance, according to GB/T17650 and GB/T17651 test: smoke density and light transmittance ≧70%; electrical conductivity ≦10µS/mm; pH value ≧4.3.

- After the cable is soaked in mineral oil or fuel oil, it passes the combustion test specified in IEC60332.

- The cable has passed the test of GB/T3048 resistance to mineral oil and fuel oil.