In today’s fast-paced industrial landscape, reliable and high-performing cables are essential for powering mission-critical equipment, transmitting data, and ensuring the smooth operation of your facility. Selecting the appropriate solution can feel overwhelming with an endless array of industrial cable options. However, by understanding the key factors, you can make an informed decision that optimizes performance, reduces downtime, and aligns with your unique operational requirements.

The Importance of Industrial Cable Selection:

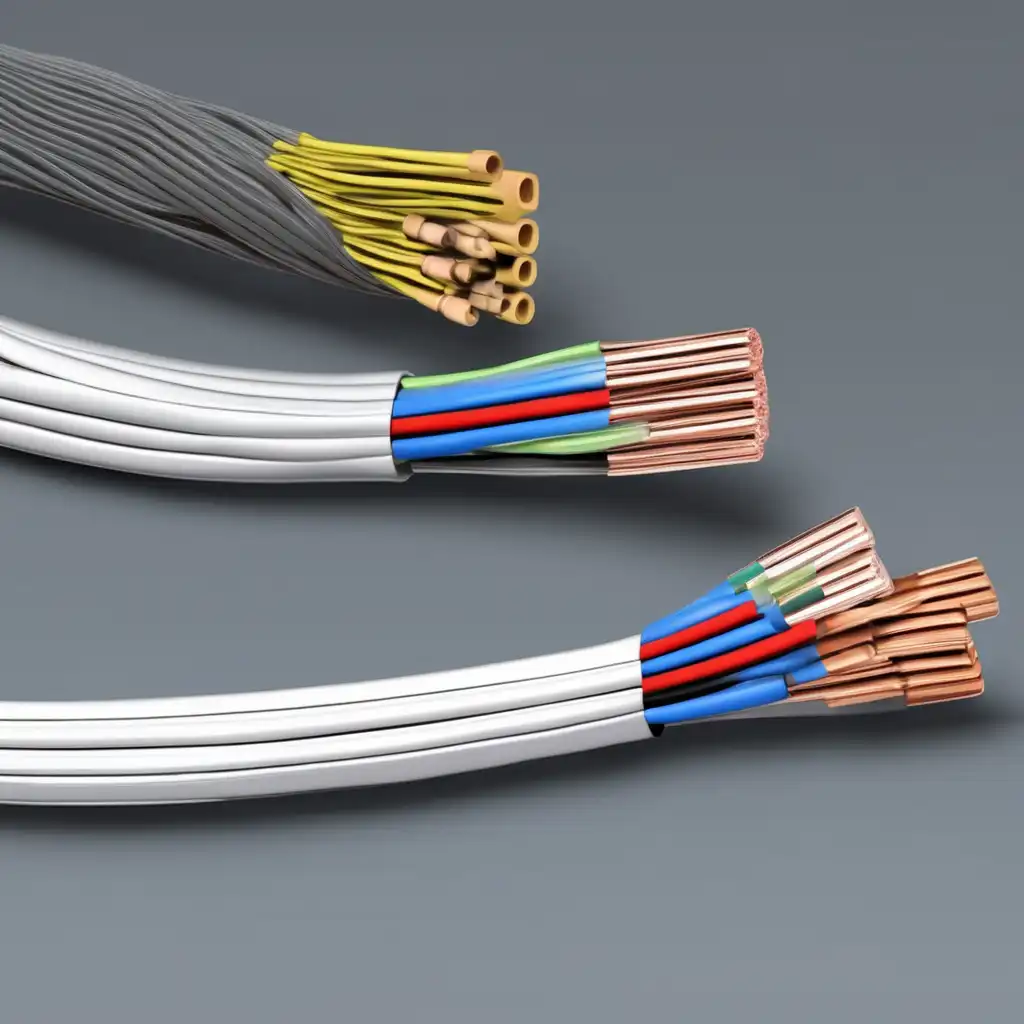

Industrial cables are the backbone of your facility, connecting critical components and enabling the efficient flow of power, data, and signals. Choosing the wrong cable can lead to many problems, from decreased productivity and increased maintenance costs to potential safety hazards and compliance issues. On the other hand, selecting the suitable industrial cable can offer a host of benefits, including:

•Improved system reliability and uptime

•Enhanced energy efficiency and cost savings

•Increased data transmission speeds and improved communication

•Reduced risk of failures, downtime, and safety incidents

•Compliance with industry standards and regulations

By carefully evaluating your specific needs and the features of different cable options, you can ensure that your industrial cable selection supports your overall business objectives and positions your organization for long-term success.

Key Factors to Consider:

There are several crucial factors to consider when choosing industrial cables. Let’s explore each one in detail:

Environmental Conditions

The environment in which your industrial cables will operate plays a significant role in their selection. Factors such as temperature, humidity, exposure to chemicals or liquids, and physical hazards can all impact the cable’s performance and lifespan. Be sure to select cables designed to withstand the specific environmental conditions in your facility, ensuring they can reliably function without degradation or failure.

Electrical Requirements:

Understand the electrical requirements of the devices and systems your industrial cables will power or connect. Consider voltage, current, and frequency factors to ensure the cables can handle the necessary electrical loads without compromising safety or performance. Additionally, pay attention to the cable’s shielding and grounding capabilities, as these features can protect against electromagnetic interference(EMI)and ground faults.

Physical Characteristics:

The physical attributes of industrial cables, such as size, weight, and flexibility, can significantly impact their suitability for your application. Cables that are too bulky or rigid may be challenging to route and install, while wires that are too thin or lightweight may not be durable enough to withstand the rigors of your industrial environment. Carefully measure the available space, bending radii, and other physical constraints to select cables that balance performance and ease of use.

Regulatory Compliance:

Depending on your industry and location, your industrial cables may need to adhere to various safety standards and regulatory requirements. These include fire safety ratings, hazardous location certifications, and compliance with organizations such as the National Electrical Code(NEC)or the International Electrotechnical Commission(IEC). Ensure your cable selection meets all relevant standards and regulations to avoid potential safety issues or legal complications.

Durability and Lifespan:

Industrial environments can be harsh, with exposure to various physical and environmental stresses. When choosing industrial cables, prioritize durability and longevity to minimize the risk of premature failure, which can lead to costly downtime and repairs. Look for abrasion resistance, crush resistance, and UV protection, and consider the cable’s overall construction and materials to ensure it can withstand the demands of your industrial setting.

Installation and Maintenance:

The ease of installation and ongoing maintenance requirements of your industrial cables can significantly impact the overall cost and efficiency of your operations. Consider the cable’s flexibility, termination options, and compatibility with your existing infrastructure to ensure a smooth installation process. Additionally, evaluate the cable’s maintenance needs, such as the frequency of inspections or the availability of replacement parts, to minimize disruptions and ensure long-term reliability.

Cost and Return on Investment:

While cost is essential, it should not be the sole factor in your industrial cable selection. Instead, focus on finding the best solution by balancing performance, durability, and long-term cost-effectiveness. Remember that the initial purchase price is just one part of the equation–you’ll also need to factor in installation, maintenance, and potential replacement costs over the lifetime of the cable.

Leveraging Expert Guidance:

Navigating the complexities of industrial cable selection can be daunting, especially for those new to the field or facing unique operational challenges. Fortunately, you don’t have to go it alone. By partnering with us, you can benefit from the expertise and guidance of seasoned professionals who can help you make an informed decision that aligns with your needs.

Look for a supplier that offers a comprehensive range of high-quality industrial cable solutions, personalized support, and technical expertise. These partners can assist you in assessing your requirements, evaluating the available options, and ensuring that your cable selection meets all relevant standards and regulations. With their help, you can confidently choose the suitable industrial cable for your application and enjoy peace of mind with a reliable, long-lasting, cost-effective solution.

As a professional industrial cable manufacturer, our industrial cables are of good quality and have a long service life. In addition, we have a strong R&D team and support various cable customization. Our industrial wires are commonly used in rail transit, aviation, shipbuilding, nuclear power, and other fields. If you need anything, please get in touch with us.

Remember, a suitable industrial cable can enhance efficiency, reduce downtime, and improve your operations’ overall productivity and profitability. Don’t settle for anything less than the best–partner with a trusted industrial cable supplier and invest in a solution that will serve you well for years.