Automotive wiring harnesses are an integral part of modern automotive design and are important connecting tissues that integrate the electrical and electronic systems of a vehicle. Understanding the components of automotive wiring harnesses is essential to understanding their functions and importance. As a professional automotive wiring harness manufacturer, we pride ourselves on providing products that embody quality, reliability, and innovation. This article aims to take a deep dive into the key components that make up automotive wiring harnesses, highlighting their importance and specific roles.

- Wires and conductors

1.1 Copper wires

Copper is the most commonly used material for wires because of its excellent conductivity, flexibility, and durability. These wires can efficiently transmit electrical signals and power throughout the vehicle.

1.2 Aluminum wires

In applications where weight reduction is critical, aluminium wires can be used. Although aluminium has a lower conductivity compared to copper, advances in materials and design have made aluminium a viable option in specific scenarios.

2. Insulating materials

2.1 Polyvinyl chloride(PVC)

PVC is often used to insulate wires because of its flexibility, cost-effectiveness, and good heat resistance. It provides a strong barrier against chemicals, oils, and mechanical wear.

2.2 Cross-linked Polyethylene(XLPE)

XLPE is an excellent insulating material for environments that require greater heat and chemical resistance. It can withstand high temperatures and provide excellent mechanical protection.

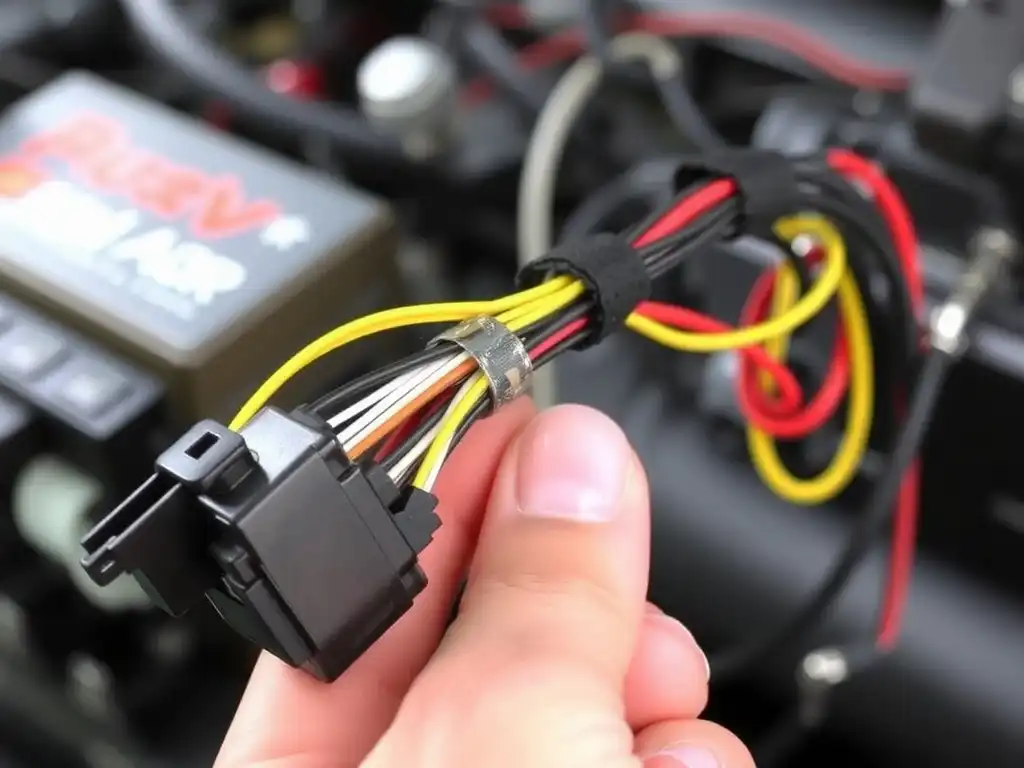

3. Connectors

3.1 Metal Connectors

Metal connectors are made of materials such as brass, copper, or aluminium and are essential for establishing reliable electrical connections. These connectors are often coated with tin, gold, or silver to improve conductivity and prevent corrosion.

3.2 Plastic Connectors

Plastic connectors wrap around metal connectors, providing mechanical and environmental protection. They are often made of durable materials such as nylon or polycarbonate to resist heat, chemicals, and mechanical stress.

4. Terminals

Terminals facilitate the connection of wires and electronic components within the vehicle. Terminals are made of conductive materials and are essential to ensure a safe and stable connection.

5. Fuses and Relays

5.1 Fuses

A fuse is a protective device that protects wiring harnesses and electronic components from overcurrent. When the current exceeds a predetermined level, the fuse melts or breaks the circuit, preventing damage.

5.2 Relays

A relay is a switching device that electronically controls a high-current circuit via a low-current signal. They effectively control a variety of circuits within a vehicle, improving performance and safety.

6. Fuse Boxes and Junction Boxes

6.1 Fuse Boxes

Fuse boxes serve as centralized hubs that hold multiple fuses. This organization simplifies the process of monitoring and replacing fuses, which improves maintenance efficiency.

6.2 Junction Boxes

Junction boxes provide a centralized point for connecting multiple circuits within a wiring harness. They help simplify assembly and maintenance processes while ensuring system wiring.

7. Protective Tubing and Conduit

7.1 Corrugated Tubing

Corrugated tubing provides excellent mechanical protection, protecting wiring from abrasion, impact, and environmental factors. They are typically made of polyethene or polypropylene to ensure long-term durability.

7.2 Heat Shrink Tubing

Heat shrink tubing provides insulation, protection, and strain relief for wire splices and connectors. When heated, it shrinks around the wire to form a tight protective seal that prevents moisture and mechanical damage.

8. Clips, Grommets and Ties

8.1 Clips

Clips secure wire harnesses in place, preventing them from sagging and moving, thus preventing wear and tear. They are made of durable plastic or metal, depending on the application.

8.2 Grommets

Grommets protect wires passing through metal or other rigid structures, preventing wear and tear and potential short circuits. They are usually made of rubber or plastic, adding an extra layer of safety.

8.3 Cable Ties

Cable ties bundle and secure wires together, keeping harnesses organized and manageable. They are usually made of nylon and are a simple and effective way to secure wires.

The components of automotive wiring harnesses are carefully designed to ensure optimal performance, safety and longevity. From wires and connectors to protective sleeves and fuses, each element plays a vital role in the overall function of the wiring system.

As a leading automotive wiring harness manufacturer, TESTECK leverages our extensive expertise and commitment to quality to provide tailored, cutting-edge wiring solutions to meet the diverse needs of the automotive industry. Our commitment to using premium materials and adhering to strict quality standards ensures our wire harnesses not only meet but exceed industry expectations.

TESTECK-Your trusted partner for high-quality automotive wire harness solutions.