In the vast domain of electrical wiring, FEP wire stands out as a remarkable choice for various applications, offering exceptional attributes that cater to the demanding requirements of numerous industries. This article delves into the intricacies of FEP wire, its beneficial properties, applications, and why it is increasingly becoming the go-to solution for professionals seeking reliability and performance in electrical wiring.

Understanding FEP Wire

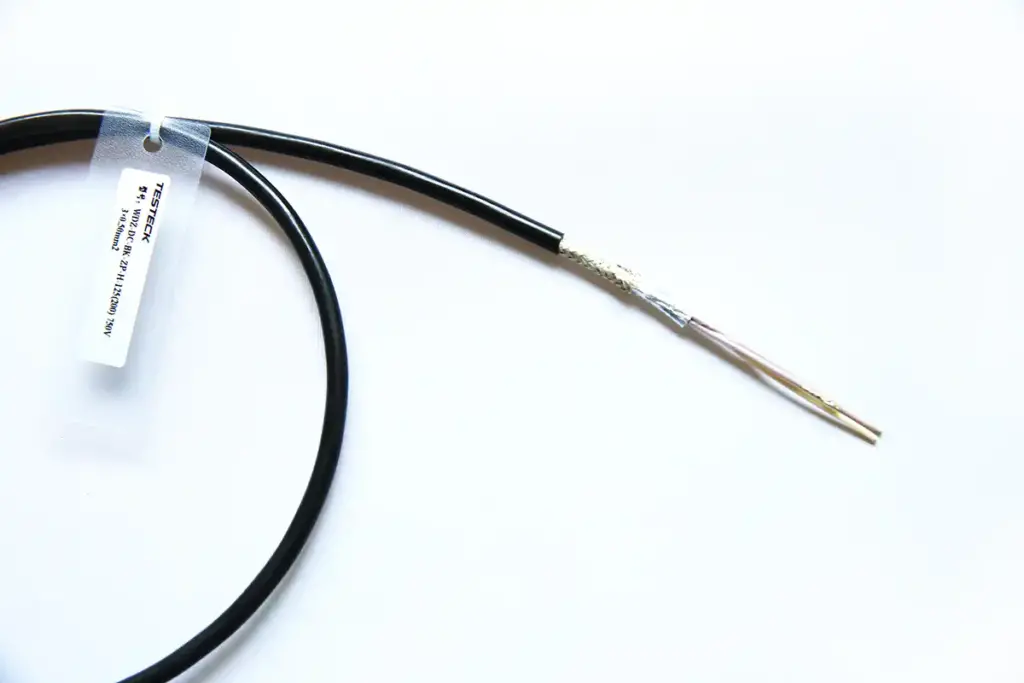

Fluorinated Ethylene Propylene, commonly abbreviated as FEP, is a type of fluoropolymer with high resistance to heat, chemical reactions, and electrical Insulation. Thus, FEP wire refers to electrical wire or cable that is coated with an FEP compound to harness these resistance properties. This coating protects the wire and enhances its performance across various parameters.

Critical Properties of FEP Wire

Temperature Resistance: FEP wires can withstand a wide temperature range, typically from -70 °C to +200 °C, making them suitable for harsh environmental conditions.

Chemical Resistance: They exhibit unparalleled resistance to various chemicals, including acids, bases, and solvents.

Electrical Insulation: Offering excellent dielectric properties, FEP wires are ideal for applications requiring minimal electrical interference.

Durability: The mechanical strength and toughness of FEP wires ensure longevity and reliability, even in demanding applications.

Water Absorption With extremely low water absorption rates,FEP wires maintain their integrity in moist conditions.

Fire Resistance: These wires are highly resistant to flame, contributing to safety in fire-prone areas.

Applications of FEP Wire

FEP wires are versatile and find applications across diverse fields, including

Aerospace: Due to their high-temperature threshold and durability.

Automotive: For vehicle wiring that demands chemical and thermal resistance.

Telecommunications: In environments requiring high signal integrity.

Medical Devices: Where sanitation and resistance to sterilization processes are crucial.

Environmental Monitoring Equipment: Given their resilience in harsh conditions.

Choosing FEP Wire Why It Matters

Selecting the correct type of wire is critical for any application’s safety, efficiency, and longevity.FEP wire, with its unique blend of properties, offers a compelling case over standard wiring solutions. It ensures operational reliability, enhances safety protocols, and extends the lifespan of electrical systems, particularly in specialized applications where standard wires might fail.

Maintenance and Care

Although FEP wires are designed for durability and resistance, proper installation and occasional inspections are recommended to ensure optimal performance over time. It is crucial to ensure that the wire is suitably rated for its intended application.

FEP wire offers an unparalleled combination of heat resistance, chemical inertness,and electrical Insulation,making it an invaluable component in critical and demanding applications. Its adaptability across industries–from aerospace to medical devices–is a testament to its exceptional properties. When selecting wiring solutions, FEP wire is a premier choice for professionals seeking reliability, safety, and performance. Contact us for FEP wire prices.