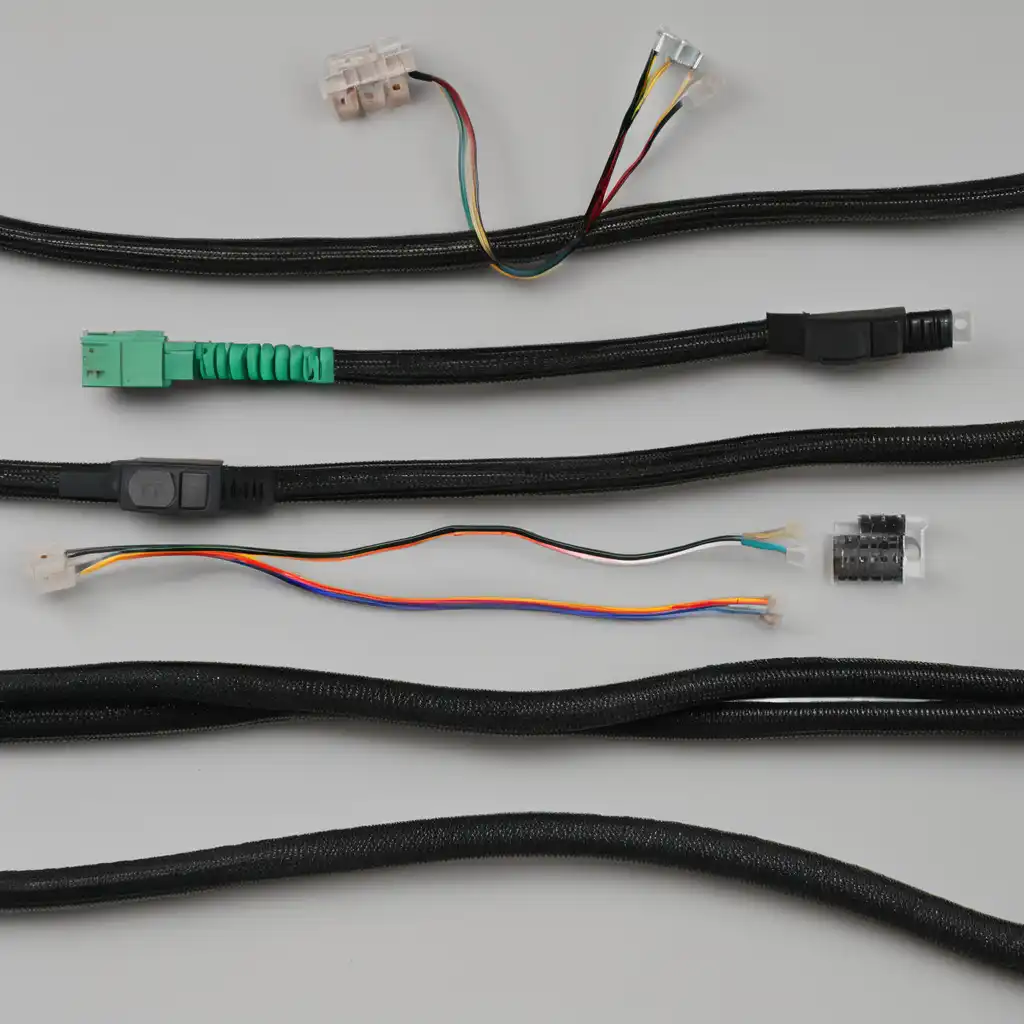

The importance of well-designed and reliable wiring harnesses cannot be overemphasized in today’s complex electrical systems, whether they are automotive, aerospace, industrial machines, or consumer electronics. As a specialized wiring harness manufacturer, we understand that choosing the right harness is critical to the success of your project or product. Here are a few key considerations to keep in mind when purchasing a wiring harness.

- Customization Capabilities

Off-the-shelf harnesses may fulfill basic needs, but most applications have specific requirements. These requirements may include unique environmental conditions, specific electrical specifications, and space constraints within the product. A professional wiring harness manufacturer should offer customization options to meet your specific needs, ensuring that the harness fits your application perfectly without any compromises.

2. Material Quality

The materials used in a wiring harness have a direct impact on its durability and performance. High-quality wires, connectors, and jacketing materials ensure that the harness can withstand environmental stresses such as high temperatures, humidity, and chemical corrosion. When purchasing a wiring harness, be sure to ask about the grade and specifications of the materials used. Choosing higher-quality materials can significantly extend product life and reliability.

3. Manufacturing Standards and Compliance

Different industries and regions have their own set of standards and regulatory requirements. For example, the automotive industry may require wire insulation that complies with ISO 6722, while aerospace applications may require harnesses that comply with AS50881. Professional harness manufacturers should not only familiarize themselves with these standards but also ensure that their products comply with them. This not only ensures the quality and safety of your harnesses but also facilitates a smoother regulatory approval process for your products.

4. Engineering and design support

A well-designed harness should optimize space, minimize signal interference, and reduce the risk of electrical failure. Specialized manufacturers provide engineering and design support to ensure that the harness meets the electrical and mechanical requirements of your application. This service is invaluable for identifying potential problems early in the design phase, saving time and resources in the long run.

5. Robust Test Programs

The reliability of a wiring harness is proven through rigorous testing. This includes tests of electrical function, durability under environmental stress, and mechanical robustness. A responsible manufacturer will have a comprehensive testing regime that every harness must pass before shipment. Ask about the test program to ensure that the harness operates as intended under real-world conditions.

6. Scalability

Whether your project is in the prototype stage or ready for mass production, it is vital to consider manufacturing scalability. A specialized harness manufacturer will be able to smoothly transition from low to high-volume production while maintaining quality and on-time completion. Discuss scalability options and lead times with your manufacturer to ensure they can meet the needs of your project.

7. Cost Effectiveness

Cost is always a consideration in product development and manufacturing. However, it is important to balance cost with quality and reliability. Specialized manufacturers can provide cost-effective solutions without compromising the quality of components or manufacturing processes. They can do this through efficient design, bulk purchasing of materials, and optimized production techniques.

8. After-sales support

Finally,after-sales support is an important aspect of any purchase. This includes technical assistance during installation and the resolution of any issues that may arise during the product’s lifecycle. Ensuring that your manufacturer is committed to providing a comprehensive after-sales service is essential to maintaining the performance and reliability of your product over time.

Choosing the right wiring harness is a critical decision that can affect the performance, reliability, and safety of your application. As a specialized wiring harness manufacturer, we are committed to providing custom solutions, high-quality materials, compliance with industry standards, and robust engineering and testing processes. By considering these key factors when purchasing a wiring harness, you can ensure the success of your project while building a reliable partnership with a manufacturer committed to meeting your needs.