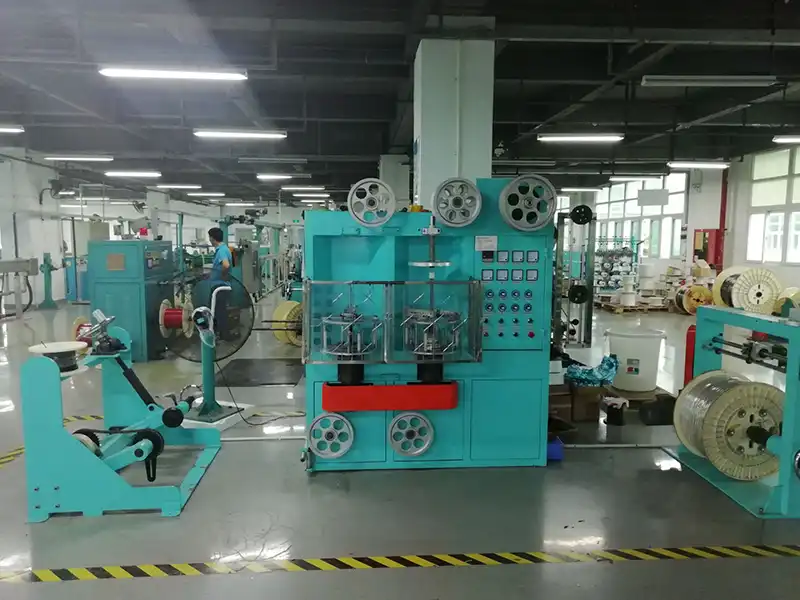

The type of wire used in automotive applications plays a vital role in ensuring the reliability and functionality of the vehicle’s electrical system. Modern vehicles are equipped with a complex network of electrical systems that control everything from the engine to entertainment features. As a professional automotive wiring harness manufacturer, our focus is on utilizing the right type of wire to meet stringent automotive industry standards. This article explores the various types of wire used in automotive applications and highlights our expertise in providing quality wiring harness solutions.

- Main Wire Types

1.1 Copper Wire

1.1.1 Tinned Copper Wire

Copper is the most commonly used conductor material in automotive wiring due to its excellent conductivity, flexibility, and durability. Tinned copper wire is often used because the tin coating has enhanced corrosion resistance, which is critical to the life and reliability of the wire in the harsh automotive environment.

1.1.2 Bare Copper Wire

Bare copper wire is also common, especially in protected environments where corrosion resistance is less important. It has excellent conductivity and is often used in short-term applications or where weight is not a high requirement.

1.2 Aluminum Wire

Another option is aluminium wire, which is lighter than copper and can be used where weight reduction is a must. While it is less conductive than copper, advances in aluminium alloy composition and processing make it a viable alternative in some cases. However, it requires special connectors and careful handling to avoid issues such as electrochemical corrosion.

2. Insulation Materials

2.1 Polyvinyl Chloride(PVC)

PVC is a popular insulation material because of its flexibility, cost-effectiveness, and reasonable heat resistance. It resists chemicals, oils, and sols well, making it suitable for a variety of automotive environments.

2.2 Cross-linked Polyethylene(XLPE)

XLPE insulation is known for its excellent thermal and mechanical properties. It can withstand higher temperatures than PVC and offers excellent abrasion and chemical resistance. This makes it ideal for under-the-hood applications and other harsh environments.

2.3 Teflon(PTFE)

Teflon insulation is used in high-performance applications where extreme temperatures and chemical exposure are common. Its excellent thermal stability and low friction properties make it suitable for specialized automotive systems.

3. Specialty Wire Types

3.1 Fusible Links

Fusible links act as protective devices in automotive electrical systems. They are designed to fuse or melt under specific conditions such as overload or short circuit, thus preventing damage to more critical components. These wires are often made of special alloys that have higher resistance compared to ordinary wires.

3.2 Shielded Cables

Shielded cables are used in applications where electromagnetic interference(EMI)or radio frequency interference(RFI)could affect the performance of the electrical system. The shield, made of braided copper or aluminium foil, helps minimize such interference, ensuring the integrity of the transmitted signal.

3.3 Battery Cables

Battery cables are essential for connecting the vehicle battery to the electrical system. They are typically made of heavy gauge copper wire and feature rugged insulation to handle high current loads and resist corrosion and physical wear.

4. Standards and Compliance

4.1 ISO 6722

ISO 6722 is the international standard for automotive electrical wiring. It outlines the requirements for electrical wiring used in road vehicles, covering aspects such as conductor material, dimensions, insulation properties, and performance standards.

4.2 SAE J1128

SAE J1128 is a widely recognized North American standard that specifies requirements for low-voltage main cables for automotive use. It includes guidelines for conductor size, insulation materials, temperature ratings, and test methods.

4.3 OEM Specifications

Original Equipment Manufacturers(OEMs)often have specific requirements for their electrical systems, requiring custom wire specifications that meet their design and performance standards. As a professional automotive wire harness manufacturer, we ensure compliance with these unique OEM standards.

Selecting the right type of wire for automotive applications requires consideration of multiple factors, such as conductivity, weight, high-temperature resistance, and environmental conditions. Common conductor materials include copper and aluminium, each of which offers unique advantages. Appropriate insulation materials such as PVC, XLPE, and Teflon are essential to protect the wires from the harsh automotive environment.

Specialized wires such as fuse links, shielded cables, and battery cables play a vital role in maintaining the safety and efficiency of automotive electrical systems. Compliance with industry standards such as ISO 6722 and SAE J1128, as well as specific OEM specifications, is critical to ensure quality and reliability.

At TESTECK, we pride ourselves on our expertise in manufacturing high-quality automotive wiring harnesses that meet the stringent requirements of the automotive industry. Our commitment to precision, quality, and innovation ensures our wiring harnesses deliver outstanding performance, reliability, and safety.

TESTECK-Your trusted partner for superior automotive wiring harness solutions.