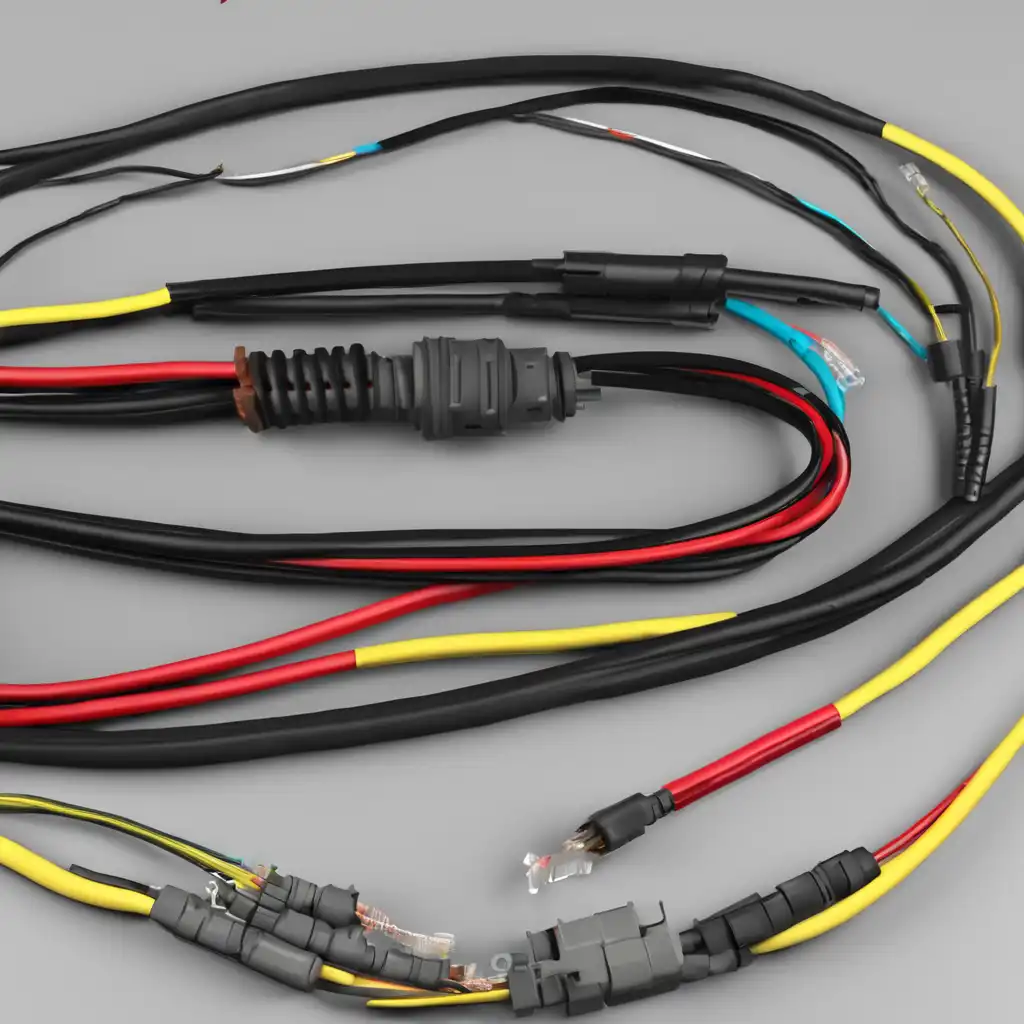

In the world of electrical engineering and manufacturing, wiring harnesses play a key role in simplifying complex wiring systems, effectively reducing the risk of errors and improving overall reliability and performance. As a specialized wire harness manufacturer, we understand the critical importance of selecting the right type of wire for a variety of applications, from automotive to aerospace and consumer electronics. This choice not only affects the functionality and safety of the harness but also its durability and efficiency. Let’s dive into the types of wire commonly used in wiring harnesses and the characteristics that make them suitable for different environments.

- Copper Wires

Copper is by far the most commonly used wire material in wiring harnesses because of its excellent conductivity and flexibility. Copper wire facilitates efficient current flow, making it ideal for transmitting power and signals without significant energy loss. In wire harness applications, you’ll find copper wire in a variety of forms:

Stranded Copper Wire: This consists of multiple small gauge wires stranded together for increased flexibility and fatigue resistance, which is critical for applications involving repetitive motion or vibration.

Solid Copper Wire: Made from a single piece of copper, it is stronger than stranded wire but less flexible. Solid copper wire is typically used where there is less movement, providing reliability and robustness.

- aluminum wire

Compared to copper, aluminum wire is lighter and cheaper but has excellent electrical conductivity. These properties make aluminum wire an attractive alternative, especially in the automotive and aerospace industries, which prioritize weight reduction and cost reduction. However, aluminum has a higher resistance to corrosion and susceptibility to corrosion, so special coatings or alloys, such as those alloyed with copper or other metals, are often required to improve its performance and durability.

- Tinned copper wire

To solve problems such as corrosion and to improve solderability, copper wire is usually coated with a thin layer of tin. Tinned copper wire is especially useful in environments that require exposure to moisture and other corrosive elements. The tin coating protects the copper underneath from oxidization while maintaining the wire’s excellent conductivity.

- nickel-plated copper wire

Nickel-plated copper wire is an excellent choice for environments with extreme temperatures. Nickel plating enhances the wire’s ability to withstand high temperatures while also providing corrosion resistance. These properties make nickel-plated copper wire particularly suitable for high-temperature applications such as engine compartments and industrial machinery.

- Silver Plated Copper Wire

Like nickel-plated wires, silver-plated copper wires are designed to operate under harsh conditions and offer excellent thermal and electrical conductivity. Silver plating is especially useful in high-frequency applications where maintaining signal integrity is critical, making these wires a common choice for telecom and military applications.

- CCA (Copper Clad Aluminum) Wire

CCA wires consist of an aluminum core coated with copper, providing a good balance between the lightweight properties of aluminum and the superior conductivity of copper. These wires are typically used in applications where weight and cost are critical factors, but where the superior conductivity of copper is also required.

Choosing the Right Wire:

Selecting the right type of wire for a wire harness requires consideration of several factors, including electrical requirements, environmental conditions, mechanical requirements, and cost constraints. As a leading wire harness manufacturer, we make it a priority to understand these factors to provide our customers with a wire harness solution that meets their specific needs and ensures safety, efficiency, and reliability.

In short, the type of wire used in a wiring harness can significantly affect its performance, durability, and suitability for a particular application. As a trusted wiring harness manufacturer, our commitment is to utilize our expertise in selecting and assembling the best wiring assemblies to provide top-of-the-line products that fit both standard and unique project requirements. By doing so, we continue to contribute to the advancement of various industries through innovative and high-quality wiring solutions.