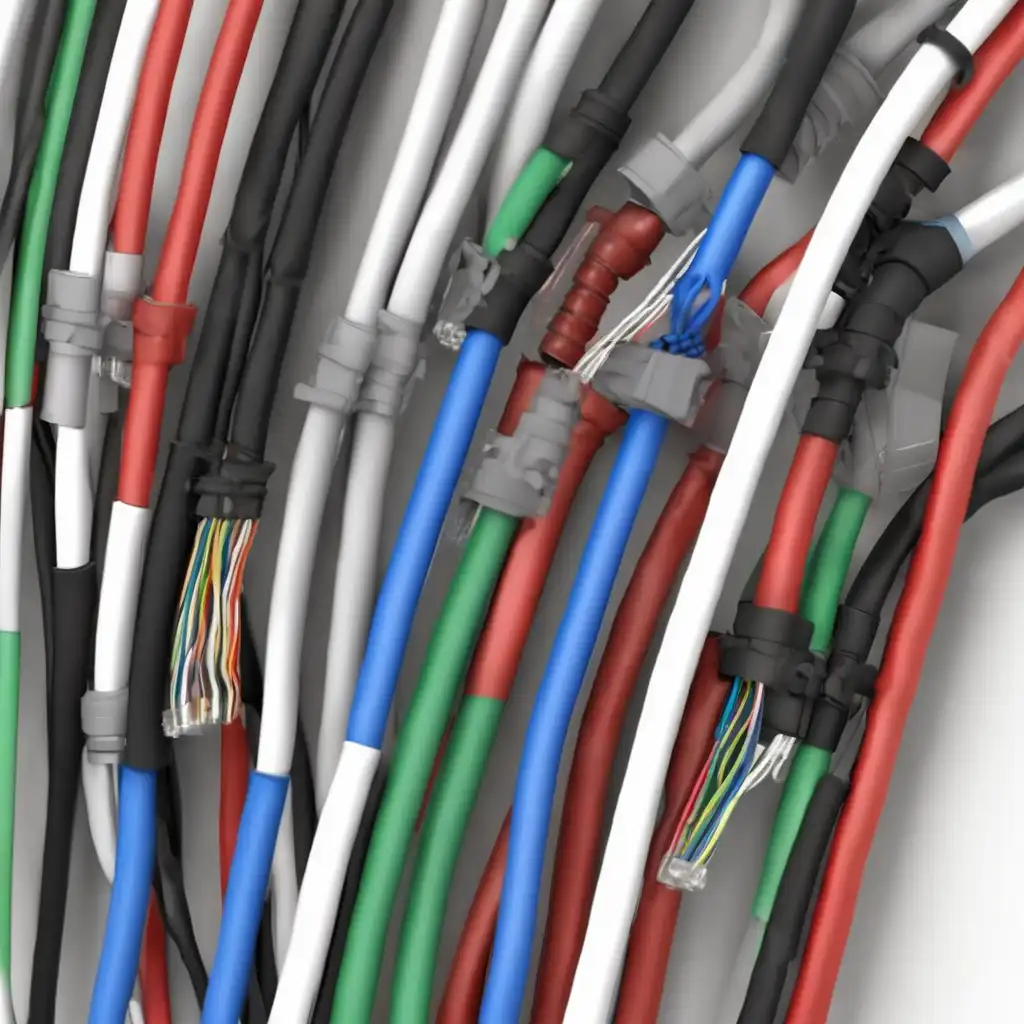

In the realm of electrical systems, the organization, safety, and reliability of connections are paramount. A wire harness is an essential component that plays a pivotal role in achieving these objectives. Simplifying complex wiring systems, protecting against environmental hazards, and enhancing overall performance, wire harnesses have become the cornerstone of various industries. Let’s explore the myriad of benefits that make wire harnesses an indispensable choice for anyone looking to optimize their electrical infrastructure.

Why Use Wire Harness?

- Simplification of Complex Systems

As technology advances, electrical systems become increasingly intricate, with a myriad of wires crisscrossing to form a network that can befuddle even the most experienced technicians. Wire harnesses bring order to this chaos, bundling wires and cables together to streamline design and maintenance. This bundling allows for easier installation and leads to much more efficient troubleshooting and repairs, saving both time and money.

2. Durability and Protection

Wire harnesses are designed to withstand harsh conditions, including extreme temperatures, vibrations, abrasions, and moisture. By encasing the sensitive wiring in a durable outer sheath, wire harnesses protect the integrity of the electrical system against external damage. This is especially crucial in industries such as automotive, aerospace, and marine, where exposure to hostile environments is commonplace. The longevity of your electrical system is substantially increased, ensuring both performance and safety.

3. Enhanced Safety

With the organization comes increased safety. Wire harnesses reduce the risk of electrical fires by keeping wires insulated from each other and combustible materials. They also prevent shorts and electrical shocks, making them an essential component in maintaining a safe operating environment. This is not just beneficial for the safety of the equipment but is also critically important for the protection of personnel.

4. Space Efficiency

The consolidation provided by wire harnesses leads to an optimized use of space. By eliminating loose cables and reducing the footprint of the wiring system, there’s more room for other critical components or, in some applications, more spacious interiors for operators and passengers. This space efficiency also contributes to the overall aesthetics of the system, providing a clean, organized look that is as professional as it is functional.

5. Cost-Effectiveness

Investing in a wire harness can significantly reduce costs in the long term. By minimizing the risk of electrical problems and system failures, the need for repairs and replacements is decreased. Moreover, the efficiency of installation and maintenance when using a wire harness system can substantially cut down on labour costs.

6. Customization and Scalability

Wire harnesses can be custom-designed to meet the specific needs of any project, which makes them incredibly versatile. Whether you are running a small operation or managing large-scale production, wire harnesses can be scaled to fit your requirements. As your business grows and your needs change, wire harnesses can adapt to new configurations, ensuring that your investment in them is future-proof.

7. Environmental Compliance

As global awareness regarding the environment grows, industries are moving towards sustainable practices. Wire harnesses can be built using environmentally friendly materials and techniques that comply with regulations like RoHS(Restriction of Hazardous Substances). Not only does this help in reducing the carbon footprint, but it also positions your business as a responsible entity that prioritizes environmental consciousness.

In Summation

Wire harnesses offer a multifaceted solution to managing and protecting the lifelines of electrical systems. They encapsulate the best practices in simplification, protection, safety, efficiency, cost-effectiveness, customization, scalability, and environmental compliance. Investing in a quality wire harness is not just a practical decision for your current electrical needs; it is a move towards a more organized, reliable, and future-ready operation. Whether you operate in the automotive, aerospace, consumer electronics, or any other industry with complex wiring needs, the wire harness will provide you with peace of mind and a competitive edge in your market.

For any business looking to ensure the safety, efficiency, and reliability of their electrical systems, the question isn’t whether to use a wire harness—it’s why you haven’t started using one already.

TESTECK is a professional cable harness manufacturer, if you need a cable harness, welcome to talk to us.