Automotive wiring harness classification

Auto harness solution

Vehicle wiring harness classification:

front cabin wiring harness assembly,

engine wiring harness assembly,

gearbox wiring harness assembly,

instrument wiring harness assembly,

indoor wiring harness assembly,

door wiring harness assembly (four different doors),

ceiling wiring harness assembly,

rear luggage Box wiring harness assembly,

battery positive and negative wiring harness assembly,

airbag wiring harness assembly and other parts.

However, the division of the wiring harness has a lot to do with the structure and assembly process of the vehicle.

In order to achieve a simple structure and easy disassembly and assembly for specific models,

the modular design will be adopted in the wiring harness as much as possible to reduce the circuit,

and will not stick to these classifications.

Front cabin wiring harness assembly

The environment of the front cabin wiring harness is the worst, with many parts and relatively small space.

Therefore, when arranging the front cabin wiring harness, factors such as waterproof, heat insulation, and vibration must be fully considered to protect and fix the wiring harness.

The main electrical components in the front cabin: powertrain and its accessories (currently there are fewer models with rear-mounted engines),

ABS system, lamps, wiper washing system, power system,

central electrical box (some models are also placed indoors) ) and some other electrical devices.

Powertrain wiring harness

The powertrain wiring harness is also located in the front cabin, including the engine wiring harness and transmission wiring harness.

There are many sensors and actuators on the powertrain.

The positional relationship of these sensors should be fully considered, and the wiring harness can be fixed by using the fixed points on the powertrain or by using the fixed points on it to design brackets.

And pay attention to waterproof, heat insulation, heat dissipation and vibration.

The electrical components of the powertrain are mainly sensors and actuators on it,

including crankshaft position sensor, phase sensor, vehicle speed sensor, knock sensor,

water temperature sensor, oil temperature sensor, electronic throttle, idle speed control valve,

carbon canister solenoid valve , ignition coil, fuel injector, EGR, CBR, vortex control valve,

high-pressure oil pump, pressure temperature sensor, boost pressure sensor, position switch, reverse switch, etc.

On automatic transmissions, multiple sensor interfaces are often integrated.

Dashboard wiring harness assembly

The instrument panel concentrates most of the operation switches and display devices of the whole vehicle,

and gathers multiple control units. At the same time, the connecting parts of the wiring harness are often designed on both sides of the instrument panel.

Therefore, the instrument panel wiring harness is one of the most complicated wiring harnesses in the vehicle. one.

In the instrument panel, there are mainly the following electrical components: HVAC, audio system, airbag, instrument electrical box, BCM, ECU, TCU, brake switch,

electronic accelerator pedal, clutch switch, cigarette lighter, backup power supply and various switches components (such as combination switch, alarm switch, etc.).

Indoor harness assembly

The indoor (floor) wiring harness is the longest and largest wiring harness in the whole vehicle.

It runs through the entire body and is the first wiring harness to be considered in the design of the vehicle.

He involves the most body problems, and the most via problems that need to be considered.

There are relatively few electrical components in the indoor wiring harness,

such as electric seats and heating, electronic oil pumps, seat belt switches,

rear wheel speed sensors, corner sensors, etc., but the positions are relatively scattered.

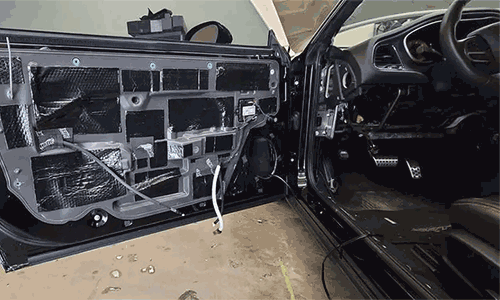

door harness assembly

The door wiring harness (four different doors) is relatively small,

and there are relatively few issues to consider, mainly the door’s movement mechanism,

door rubber parts and fixing. The main electrical components of the door wiring harness are glass lift switches and motors,

electric rearview mirrors, horns, door locks, interlocks, threshold lights, side turn signals, child safety switches, etc.

Other wiring harness

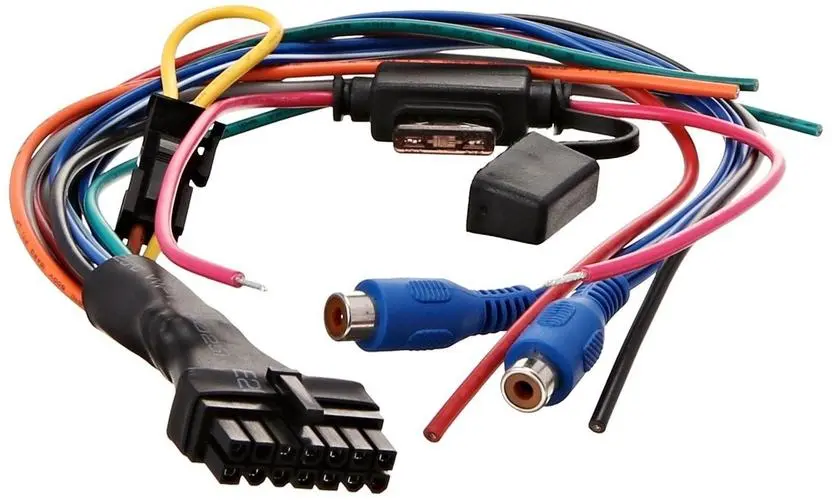

Instrument extension combination cable

In addition to the above wiring harnesses, there are still some smaller other wiring harnesses on the vehicle,

such as battery positive and negative wiring harnesses, rear defrosting positive and negative wiring harnesses,

ceiling wiring harnesses, airbag wiring harnesses, rear cover wiring harnesses, etc.

These smaller wiring harnesses usually have the following electrical components: battery, airbag, rear defrost, license plate light, dome light, sunroof, trunk switch, etc.

Battery positive and negative wire harness assembly: the battery, starter, generator and ground connected by the positive and negative wire harness of the battery.

High current, shock resistance and wear resistance need to be considered.

Ceiling harness assembly: Its main connected electrical components are some electrical components

such as dome lights, sunroofs, vanity mirror lights, etc. Vias and pinning need to be considered.

Airbag harness assembly:

It is mainly connected to the electrical device airbag, and the reliability of the connection is mainly considered, such as gold-plated terminals.

Rear trunk harness assembly: the main connection is the license plate light, rear door locker and other electrical components.

The movement of the back cover needs to be considered.