Instrument cables are cables specifically used for signal transmission and control lines in instrument instruments, suitable for low-voltage environments. It is used in industrial fields to connect instruments and control equipment, ensuring accurate signal transmission and reliable control.

The main types of instrumentation cables include the following:

1. Instrument analog signal transmission cable: used to transmit analog signals, such as temperature, pressure, flow, etc.

2. Instrument switch signal transmission cable: used to transmit switching signals, such as switching input and output.

3. Thermocouple extension cable: used to connect the thermocouple and transmit the temperature signal to the measuring device.

4. Thermal resistance extension cable: used to connect the thermal resistance and transmit the temperature signal to the measuring device.

5. Power supply cable: used to provide power supply to instrument equipment.

6. Grounding cable (wire) : used to establish a reliable grounding connection between the instrument and the ground.

7. Communication cable: used to connect the communication transmission between the instrument and the control system.

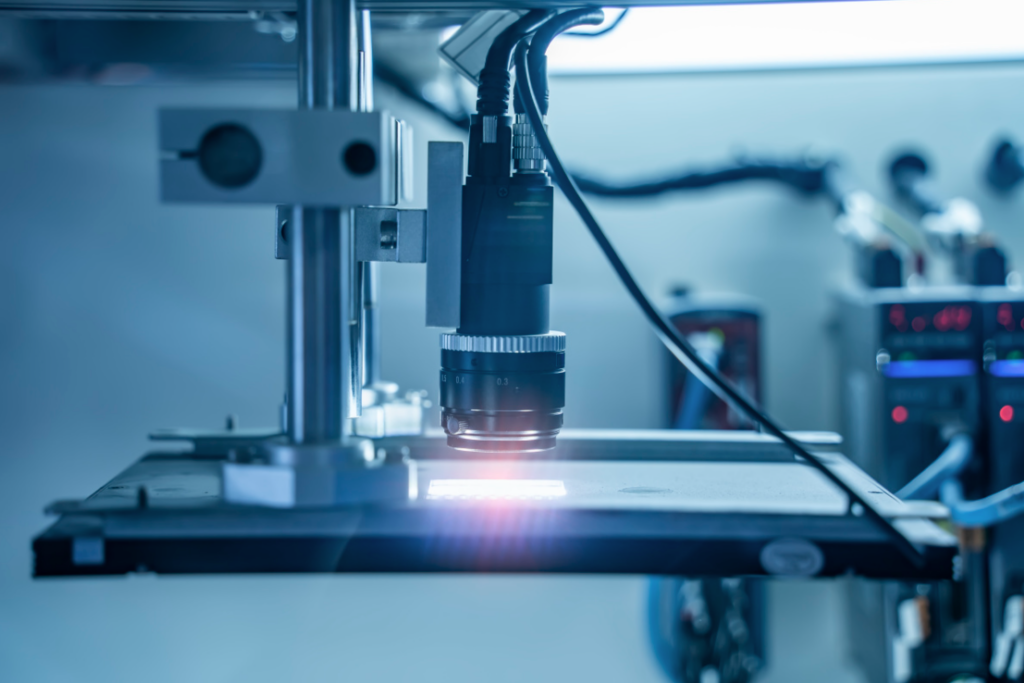

Instrument cables are widely used in various industrial automation scenarios:

1, control class: used to transmit a variety of control signals, its rated voltage is generally 450/750V, can be used for the control center to connect to a variety of systems to transmit signals or control the operation of electrical components. Control cables are often used for: indicator light display, instrument indication, operation of relays and switchgear, alarm interlocking systems, etc.

2, measurement class: used to transmit analog signals, usually the current is 4-20mA, the voltage is 0~10V, such as temperature, pressure, flow, liquid level and other sensors at the end of the cable.

3, communication: transmission of telephone, telegraph, fax documents, television and radio programs, data and other electrical signals cable.

The above various types of instrument cables have their own applicable characteristics and specifications, according to the need to choose the right cable can ensure the performance and reliability of the system.

The following points should be paid attention to in the selection of instrument cables:

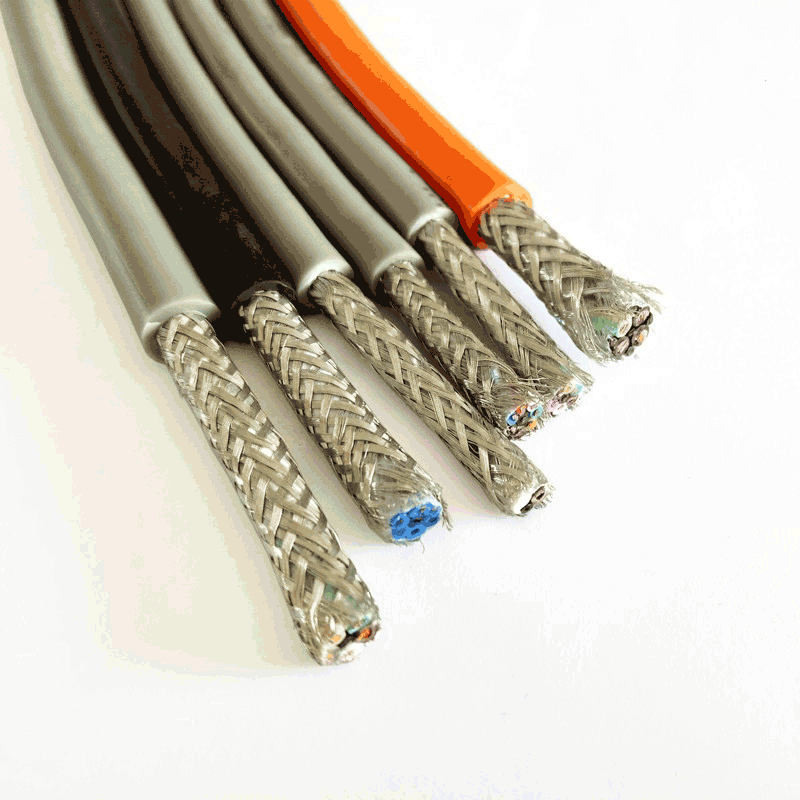

Conductor: silver-plated copper/tin-plated copper

The conductor is best coated with tin/silver on the surface, which can prevent the core wire from being oxidized in a long-term high temperature environment and improve the conductivity.

Sheath and insulation: polymer

The sheath and insulation are made of polymer materials with excellent mechanical properties, which can withstand high strength metal impact and cutting. It has very high tensile strength and can also withstand repeated bending for a long time.

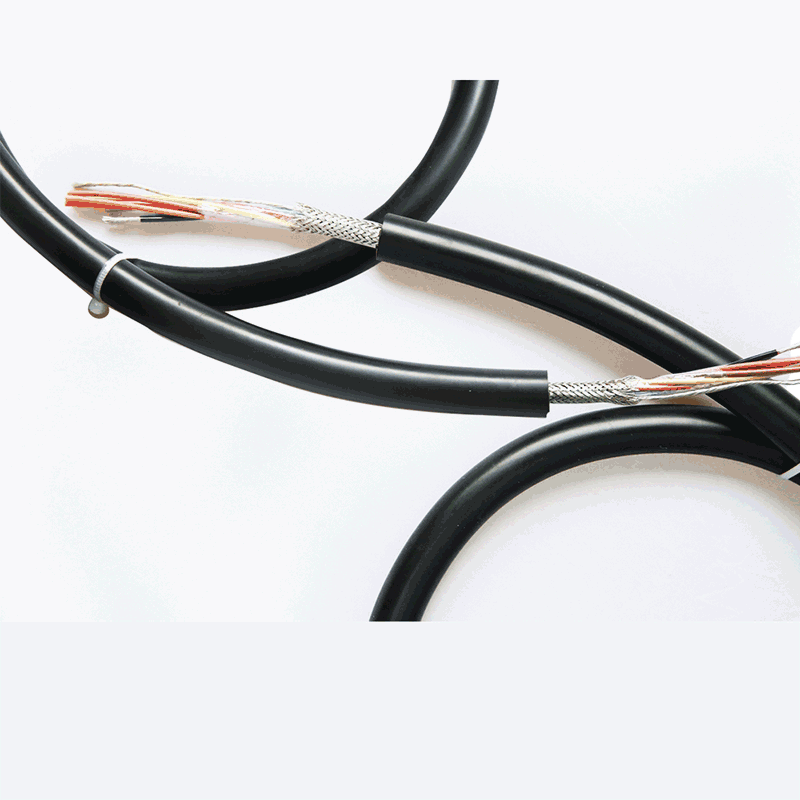

Shielding: tinned copper braided mesh shielding

Resist the interference of strong electric fields, especially strong magnetic fields, on the one hand, to successfully derive the interference signal, the very thin wire must have sufficient bending resistance.

Reinforcing layer: polymer

Selected polymer materials, mainly to prevent the damage of the shielding network insulation layer. It also enhances the overall mechanical properties of the cable.

Focusing on special cable applications and solutions, Teste produces instrumentation cables with outstanding performance. Tester’s instrumentation cables have the following features:

1. Oil resistance, wear resistance, acid and alkali resistance, corrosion resistance: These characteristics make the cable stable operation in harsh environments.

2. Waterproof and shielding performance: protect the cable from moisture and external interference to ensure the reliability of signal transmission.

3. Strong tensile strength: the structural design and material selection of the cable make it have excellent tensile strength and can adapt to various working environments.

4. Excellent voltage resistance: this means that the cable can withstand high pressure environments to ensure electrical safety and stability.

5. High reliability: Tester pays attention to quality control and production process, and its cable has high reliability and can run stably for a long time.

In addition, Testeck provides instrumentation cables produced in accordance with IEC, British, German and American standards recommended by the International Electrotechnical Commission, with excellent performance and reliability, suitable for a variety of special applications to meet the needs of different users.

At present, Testeck has a market share of more than 95% in this segment of sensor cables in the measurement field, and we hope that industry practitioners can choose reliable instrumentation cables to ensure the performance of instrumentation.